Уводзіны

Паветраны класіфікатар - гэта тып абсталявання, які выкарыстоўваецца для звыштонкага драбнення і класіфікацыі матэрыялаў, і ён шырока ўжываецца ў розных галінах, такіх як горназдабыўная прамысловасць, хімічная прамысловасць, будаўнічыя матэрыялы і г.д. З пастаянным удасканаленнем патрабаванняў сучаснай прамысловасці да тонкасці і чысціні парашка, паветраны класіфікатар стаў адным з асноўных відаў абсталявання для апрацоўкі звыштонкага парашка.

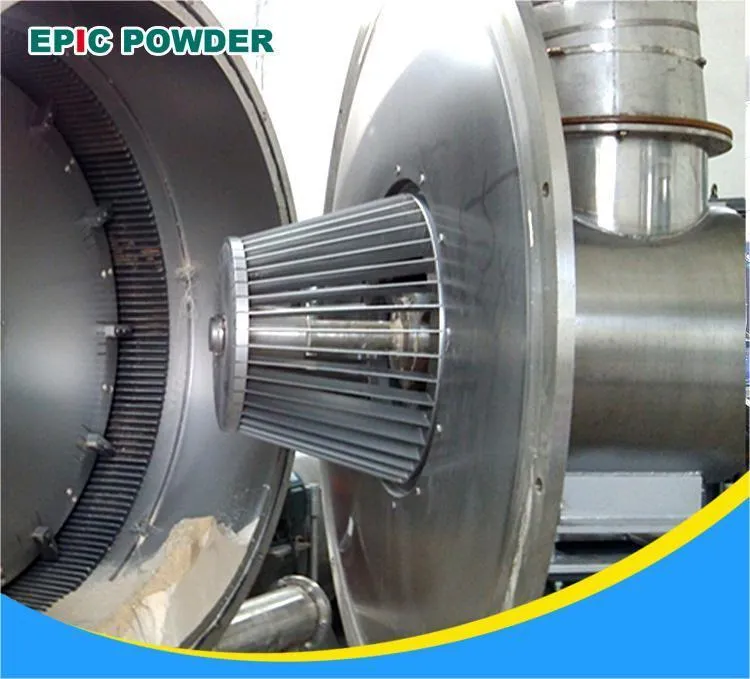

ЦіТАА «Нгдао Эпік Парашковае Машынарнае Апаратства» з'яўляецца прафесійным вытворцам абсталявання для апрацоўкі парашка. Наша прадукцыя ўключае абсталяванне для драбнення парашка, абсталяванне для класіфікацыі, абсталяванне для мадыфікацыі і адпаведнае дапаможнае абсталяванне. Паветраны класіфікатар - адзін з нашых прадуктаў, які ўключае чатыры тыпы: MJW-W, MJW-L, MJW-A, а MJL-W, з надзейнай якасцю і разумнымі цэнамі, асабліва тып MJW-W, яго прадукцыйнасць можа быць параўнальнай з паветраным класіфікатарам ZPS, вырабленым у Германіі.

Асаблівасці паветранага класіфікатара млына ад Epic Powder

◆ Стабільнае і гнуткае поле патоку, якое падыходзіць для эфектыўнага драбнення прадуктаў сярэдняй дыферэнцыяльнасці, і мае нізкае спажыванне энергіі.

◆Убудаваны высокапрадукцыйны турбапаветраны класіфікатар забяспечвае вузкае размеркаванне памераў часціц, стромкую адсечку і высокую дакладнасць класіфікацыі.

◆Сістэма працуе з вялікім аб'ёмам паветра і нізкай тэмпературай памолу, што робіць яе прыдатнай для апрацоўкі цеплаадчувальных матэрыялаў.

◆ Шліфавальныя малаткі і зубчастая кавалкі выраблены з ультрацвёрдых матэрыялаў, а ўсе лёгка зношвальныя дэталі апрацаваны зносаўстойлівымі сродкамі. Гэта значна падаўжае тэрмін службы і значна памяншае забруджванне прымешкамі жалеза.

◆ Ён можа адпавядаць патрабаванням цалкам чыстай керамічнай вытворчасці.

◆ Мае высокую ступень аўтаматызацыі. Уся сістэма працуе пад цалкам закрытым адмоўным ціскам, без забруджвання пылам, а эфектыўнасць збору перавышае 99,91 TP3T.

◆ Падыходзіць для драбнення лёгкаўзгаральных і выбуховых матэрыялаў.

Кіраўніцтва па бяспечным выкарыстаннілініі

① Паслядоўнасць запуску і прыпынку

— Паслядоўнасць запуску: Выконвайце прынцып запуску без нагрузкі. Спачатку ўключыце вентылятар. Пасля стабілізацыі патоку паветра запусціце млыні, нарэшце, пачаць падаваць матэрыялы.

— Паслядоўнасць выключэння: спачатку спыніце падачу матэрыялаў. Пасля апаражнення абсталявання спыніце млын. Нарэшце, выключыце вентылятар, каб прадухіліць закаркаванне рэшткамі матэрыялаў.

② Кантроль матэрыялаў

— Кантралюйце вільготнасць матэрыялаў (звычайна ≤ 5%). Занадта высокая вільготнасць можа выклікаць адгезію або закаркаванне.

— Пазбягайце траплення прымешак з празмерна высокай цвёрдасцю (напрыклад, металаў). Выдаленне жалеза або папярэднюю апрацоўку варта праводзіць загадзя.

③ Тэхнічнае абслугоўванне і праверка

— Праверце, ці не пашкоджаныя і не аслабленыя такія кампаненты, як вентылятар, класіфікацыйнае кола і трубаправоды, і ці добрая іх герметычнасць, каб прадухіліць уцечку парашка або ўцечку паветра.

— Рэгулярна правярайце, ці дастаткова змазачнага алею ў ключавых дэталях, такіх як падшыпнікі (тэмпература падшыпнікаў павінна быць ≤70℃) і шасцярні, каб пазбегнуць перагрэву або пашкоджанняў, выкліканых сухім трэннем.

— Праверце, ці належным чынам працуюць такія прылады бяспекі, як ахоўныя крышкі, кнопка аварыйнага прыпынку і манометры, каб прадухіліць механічныя траўмы або анамальны ціск.

④ Бяспека

— Абсталюйце антыстатычным абсталяваннем для выдалення пылу (напрыклад, мяшковы фільтр) каб пераканацца, што канцэнтрацыя пылу ў рабочай зоне ніжэйшая за ніжнюю мяжу выбуханебяспекі.

— Аператары павінны насіць пылаахоўныя маскі, ахоўныя акуляры і берушы, каб пазбегнуць удыхання пылу і траўмаў, выкліканых шумам.

— Падчас працы забараняецца адчыняць люкі для тэхнічнага абслугоўвання, каб пазбегнуць траўмаў ад хуткасных кампанентаў.

⑤ Патрабаванні да ўстаноўкі

— Абсталяванне павінна быць усталявана ў месцы з добрай вентыляцыяй і пазбягаць асяроддзяў з высокай тэмпературай і высокай вільготнасцю.

— Падстава абсталявання павінна быць выраўнавана і адкалібравана, каб паменшыць вібрацыю.

⑥ Кіраванне ў надзвычайных сітуацыях

— Пры адключэнні абсталявання для тэхнічнага абслугоўвання адключыце электрасілкаванне і павесьце папераджальны знак, каб прадухіліць выпадковы ўпуск.

— Абсталяваць пажаратушальныя сродкі для барацьбы са самазагараннем або іншымі раптоўнымі пажарамі.

⑦ Запіс і адсочванне

— Стварыць файл тэхнічнага абслугоўвання і запісваць такую інфармацыю, як замена зносу, ліквідацыя няспраўнасцяў і г.д., каб праводзіць рэгулярнае прафілактычнае абслугоўванне.

Рэгулярнае ўкараненне вышэйзгаданых мер можа значна палепшыць стабільнасць і эфектыўнасць паветранага класіфікатара, адначасова зніжаючы рызыкі для бяспекі. Для атрымання канкрэтнай інфармацыі неабходна звярнуцца да інструкцыі па эксплуатацыі абсталявання і ўнесці карэктывы ў адпаведнасці з рэальнымі ўмовамі працы.

Заключэнне

Характарыстыкі прадукцыйнасці і эксплуатацыі паветранага класіфікатара непасрэдна ўплываюць на эфектыўнасць і бяспеку вытворчасці. Кампанія Qingdao Epic Powder Machinery Co., Ltd., абапіраючыся на шматгадовы вопыт вытворчасці і назапашаныя тэхналогіі, прапануе кліентам эфектыўныя, энергазберагальныя і экалагічна чыстыя рашэнні.

Калі вам патрэбныя індывідуальныя паслугі або тэхнічныя кансультацыі, калі ласка, звяжыцеся з наміДзякуючы прафесійнай тэхнічнай падтрымцы і надзейнаму абсталяванню, кампанія Epic Powder прадаставіць вам поўны спектр паслуг да, падчас і пасля продажу, дапамагаючы вашай перапрацоўцы парашка дасягнуць больш высокіх стандартаў.