วัสดุอิเล็กโทรดลบกราไฟต์คืออะไร?

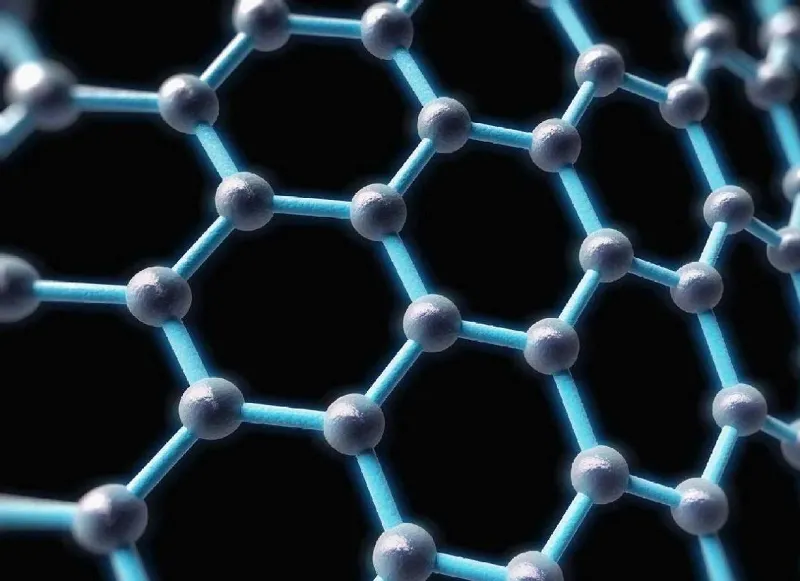

วัสดุขั้วบวกกราไฟต์เป็นส่วนประกอบหลักอย่างหนึ่งของแบตเตอรี่ลิเธียมไอออน ซึ่งมีหน้าที่หลักในการเก็บและปล่อยไอออนลิเธียม วัสดุขั้วบวกกราไฟต์ประกอบด้วยกราไฟต์เป็นหลัก ซึ่งรวมถึงกราไฟต์สังเคราะห์เทียมและกราไฟต์ธรรมชาติที่ผ่านการประมวลผลและการบำบัดพิเศษ เนื่องจากกราไฟต์เป็นสารออกฤทธิ์ในขั้วบวกของแบตเตอรี่ จึงทำให้สามารถแทรกซึมและแยกตัวของไอออนลิเธียมกลับคืนได้ระหว่างการชาร์จและการคายประจุผ่านโครงสร้างแบบหลายชั้นที่มีลักษณะเฉพาะ จึงช่วยให้เก็บและปล่อยพลังงานได้ง่ายขึ้น

ความต้องการนวัตกรรมทางเทคโนโลยีสำหรับการประมวลผลวัสดุขั้วบวกกราไฟต์

ด้วยการพัฒนาอย่างรวดเร็วของอุตสาหกรรมพลังงานใหม่ระดับโลก แบตเตอรี่ลิเธียมไอออนซึ่งเป็นสื่อกักเก็บพลังงานหลักได้กำหนดข้อกำหนดด้านประสิทธิภาพที่เข้มงวดยิ่งขึ้นสำหรับวัสดุขั้วบวกกราไฟต์ คุณภาพการประมวลผลของวัสดุขั้วบวกกราไฟต์กำหนดความหนาแน่นของพลังงาน อายุการใช้งาน และความปลอดภัยของแบตเตอรี่โดยตรง ในขณะที่การบดและการจำแนกประเภท ซึ่งเป็นขั้นตอนสำคัญในกระบวนการเตรียมการ ต้องการโซลูชันที่มีประสิทธิภาพและเป็นมิตรต่อสิ่งแวดล้อมอย่างเร่งด่วน อุปกรณ์บดเชิงกลแบบดั้งเดิมเผชิญกับความท้าทาย เช่น การใช้พลังงานสูง การกระจายขนาดอนุภาคที่ไม่สม่ำเสมอ และความบริสุทธิ์ของผลิตภัณฑ์ที่จำกัด ทำให้ไม่สามารถผลิตวัสดุขั้วบวกคุณภาพสูงได้ตามข้อกำหนด ด้วยเหตุนี้ เครื่องบดแยกอากาศจึงกลายเป็นตัวเลือกที่เหมาะสำหรับผู้ผลิตวัสดุขั้วบวกกราไฟต์ที่ต้องการยกระดับเทคโนโลยี โดยใช้ประโยชน์จากข้อได้เปรียบทางเทคนิคเฉพาะของตน

ข้อได้เปรียบหลักและมูลค่าการใช้งานของเครื่องบดแยกอากาศ

● การผสานการบดละเอียดพิเศษและการจำแนกประเภทที่แม่นยำ: สามารถทำการประมวลผลวัตถุดิบกราไฟต์จากการบดหยาบเป็นผงละเอียดมากในระดับไมครอน/ซับไมครอนได้ในขั้นตอนเดียว และกระจายขนาดอนุภาคได้เข้มข้น (ช่วงควบคุมได้ของ D50 ที่ประมาณ 3-20 μm) ช่วยปรับปรุงความหนาแน่นของแทปและความสม่ำเสมอของพื้นผิวเฉพาะของวัสดุขั้วบวกได้อย่างมีนัยสำคัญ

●ประหยัดพลังงานและประสิทธิภาพสูง:การเกรดเกรดจะช่วยหลีกเลี่ยงการบดมากเกินไป ลดการใช้พลังงาน (ลดลงประมาณ 20-30%) และปรับปรุงประสิทธิภาพการผลิต

● การกระจายและการขึ้นรูปที่มีประสิทธิภาพ: เครื่องแยกอากาศมีเครื่องแยกอากาศในตัว กังหัน เครื่องจำแนกประเภทและอุปกรณ์นำทางการไหล ซึ่งสามารถทำลายอนุภาคของกราไฟต์ที่เกาะกันเป็นกลุ่มได้อย่างมีประสิทธิภาพ โดยอาศัยผลกระทบจากการกระแทกและการเฉือน จึงสามารถขึ้นรูปอนุภาคได้ ตัวอย่างเช่น สามารถแปรรูปกราไฟต์ทรงกลมให้มีรูปร่างคล้ายมันฝรั่งเพื่อเพิ่มประสิทธิภาพการทำงานของแบตเตอรี่

● การประมวลผลที่อุณหภูมิต่ำ:ระบบหมุนเวียนอากาศแบบปิดสนิทช่วยป้องกันไม่ให้เกิดความร้อนจากแรงเสียดทานทางกล ทำให้โครงสร้างผลึกกราไฟต์มีความสมบูรณ์ ลดการเกิดออกซิเดชันหรือข้อบกพร่องระหว่างชั้นที่เกิดจากอุณหภูมิสูง และช่วยให้แบตเตอรี่มีความเสถียรในการชาร์จและปล่อยประจุ

● ไม่มีมลพิษจากโลหะและมีความบริสุทธิ์สูง: ไม่มีการสัมผัสกับสื่อโลหะ ทำให้ไม่มีสิ่งเจือปน เช่น เหล็ก และ นิกเกิล, และเป็นไปตามข้อกำหนดที่เข้มงวดด้านความบริสุทธิ์ของวัสดุของแบตเตอรี่ไฟฟ้า (สามารถควบคุมปริมาณเหล็กให้ต่ำกว่า 10 ppm ได้)

หมายเหตุ

1) เพื่อป้องกันการสึกหรอของส่วนประกอบสำคัญ เช่น ห้องบดและล้อจำแนกประเภท ขอแนะนำให้ใช้ทังสเตนคาร์ไบด์หรือวัสดุเซรามิก และตรวจสอบการกระจายขนาดอนุภาคเป็นประจำ

2) ใช้การป้องกันก๊าซเฉื่อยอย่างเคร่งครัด (เช่น ไนโตรเจน) เพื่อการบดเพื่อให้แน่ใจว่าปริมาณสิ่งแปลกปลอมแม่เหล็กน้อยกว่า 50ppm

3) อนุภาคละเอียดพิเศษที่ได้รับการจำแนกประเภท (<3μm) สามารถรีไซเคิลเพื่อใช้ในอิเล็กโทรดเชิงลบคอมโพสิตซิลิกอน-คาร์บอนเพื่อปรับปรุงการใช้ประโยชน์ของวัตถุดิบ

บทสรุป

ภายใต้กระแสการแข่งขันของ "การปรับปรุงคุณภาพและลดต้นทุน" ในอุตสาหกรรมแบตเตอรี่ลิเธียม ผู้ประกอบการแปรรูปวัสดุขั้วบวกกราไฟต์จำเป็นต้องสร้างความสามารถในการแข่งขันหลักผ่านนวัตกรรมทางเทคโนโลยี โรงสีจำแนกอากาศซึ่งมีข้อได้เปรียบที่โดดเด่นในด้านประสิทธิภาพสูง การอนุรักษ์พลังงาน และการปกป้องสิ่งแวดล้อม ไม่เพียงแต่สามารถแก้ปัญหาของกระบวนการแบบดั้งเดิมได้เท่านั้น แต่ยังช่วยให้ผู้ประกอบการผลิตผลิตภัณฑ์ระดับไฮเอนด์ที่ตอบสนองความต้องการของวัสดุขั้วบวกรุ่นใหม่ เช่น เทอร์นารีนิกเกิลสูงและคอมโพสิตซิลิกอนคาร์บอน ทำให้มีส่วนสนับสนุนที่มากขึ้นในการพัฒนาที่เข้มแข็งของอุตสาหกรรมแบตเตอรี่ลิเธียมไอออน

บริษัท ชิงเต่าอีพิคผงเครื่องจักร จำกัด เป็นผู้ผลิตอุปกรณ์แปรรูปผงระดับมืออาชีพที่มีประสบการณ์การผลิตและความรู้ทางเทคนิคมายาวนาน ผลิตภัณฑ์ของเราได้แก่ อุปกรณ์บดผง อุปกรณ์จำแนกประเภท อุปกรณ์ดัดแปลง และ อุปกรณ์เสริมที่เกี่ยวข้อง. เครื่องแยกอากาศเป็นหนึ่งในผลิตภัณฑ์ของเรา ซึ่งประกอบด้วย 4 ประเภท: เอ็มเจดับบลิว-ดับบลิว, เอ็มเจดับบลิว-แอล, เอ็มเจดับบลิว-เอ, และ เอ็มเจแอล-ดับบลิวด้วยประสิทธิภาพที่มั่นคงและราคาสมเหตุสมผล และได้รับความคิดเห็นที่ดีมากมายจากลูกค้าตลอดหลายปีที่ผ่านมา โดยเฉพาะรุ่น MJW-W ซึ่งประสิทธิภาพเทียบได้กับเครื่องบดแยกอากาศ ZPS ของเยอรมัน

ไม่ว่าคุณต้องการซื้อเครื่องบดแยกอากาศหรืออุปกรณ์แปรรูปผงอื่นๆ หรือต้องการคำแนะนำทางเทคนิค โปรด ติดต่อ Epic Powderด้วยการสนับสนุนทางเทคนิคระดับมืออาชีพและอุปกรณ์ที่มีคุณภาพที่เชื่อถือได้ Epic Powder จะมอบบริการครบวงจรแก่คุณก่อน ระหว่าง และหลังการขาย ช่วยให้การแปรรูปผงของคุณก้าวไปสู่มาตรฐานที่สูงขึ้นและตลาดที่ดีขึ้น