Aluminum powder is widely used in chemical additives, metallic pigments, fireworks, aerated concrete, metallurgy, and advanced materials. Its performance depends heavily on particle size distribution, purity, and stability. To meet the increasing demand for high-quality, precisely classified aluminum powder, a Pakistan customer sought a reliable partner capable of providing advanced grinding and air classification technology.

The customer approached Episk pulver, aiming to upgrade their existing production line and achieve consistent fine powder output with narrow particle size distribution.

Customer Challenges

Before cooperation, the Pakistan customer faced several production bottlenecks:

- Unstable Particle Size Distribution

Existing equipment produced broad PSD with excessive coarse particles, affecting application performance. - Low Production Efficiency

The grinding system required multiple passes and had limited capacity. - Potential Safety Risks

Aluminum powder is flammable and explosive, requiring strict control of temperature, airflow, and system sealing. - Insufficient Classification Accuracy

Difficulty achieving fine grades such as D50 8–15 μm and D90 < 25 μm.

The customer needed a complete solution integrating safe grinding, precise air classification, and dust-free packaging.

EPIC Pulver Solution

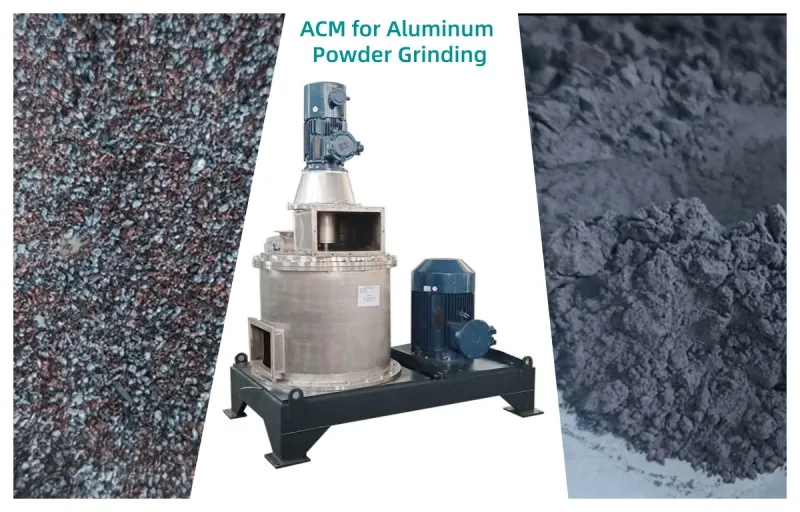

After evaluating the customer’s material characteristics and capacity goals, Epic Powder designed a Classified Grinding Production Line for Aluminum Powder, featuring:

Inert Gas-Protected Grinding System

- Nitrogen circulation to prevent oxidation and explosion.

- Controlled temperature rise to ensure material stability.

High-Efficiency Air Classifier

- Ceramic or anti-static components to prevent spark generation.

- Adjustable cut size for high-precision classification.

- Achieved D50 8–12 μm with narrow distribution (D90 < 20–25 μm).

Closed-System Material Handling

- Airtight feeding and collection system.

- Pulse-jet dust collector with anti-explosion design.

- Fully sealed discharge to prevent contamination.

Capacity & Automation Upgrades

- Produktion: 300–500 kg/h depending on fineness.

- Digital PLC control for stable operation and easy monitoring.

- Integration of real-time particle size measurement.

Project Results

After installation and commissioning, the Pakistan customer achieved significant improvements:

Ultra-Stable Particle Size Distribution:

Consistent D50 and D90 values across batches, meeting high-end application standards.

Higher Productivity:

Output increased by over 35% compared with the old system.

Enhanced Safety Level:

Inert protection and explosion-proof design ensured safe aluminum powder handling.

Reduced Operating Costs:

Lower energy consumption and fewer oversized particles reduced recycling and waste.

Stronger Market Competitiveness:

The customer successfully expanded into metallic powder coatings and chemical-grade aluminum powder markets.

Customer Feedback

The Pakistan customer expressed high satisfaction:

“Epic Powder helped us upgrade to an international-level aluminum powder production system. The stability, safety, and classification accuracy exceeded our expectations. This cooperation truly strengthened our market competitiveness.”

Konklusion

This successful cooperation demonstrates Epic Powder’s capability to deliver high-quality grinding and classification solutions for sensitive materials such as aluminum powder. With advanced engineering design, safety control, and precise classification technology, Epic Powder continues to support global customers—including those in Pakistan—in achieving high-value powder production.