Aluminum powder serves as a key metallic pigment and functional material. It finds wide use in coatings, inks, plastics, cosmetics, and aerospace. Its flaky structure delivers metallic luster and excellent shielding. Industry growth demands tighter particle size, uniformity, and purity. Traditional methods fall short. The broyeur classificateur à air for aluminum powder provides efficient ultrafine grinding. It combines high-speed impact and internal classification. This yields D97 < 10 μm ultrafine powder. It leads in air classifier mill for aluminum powder technology. This article covers principles, advantages, and applications.

Challenges and Needs in Aluminum Powder Ultrafine Grinding

Aluminum powder is a silver-white flaky powder. Its particle size usually ranges between 2–50 μm. Proper control ensures optimal coverage and brightness in coatings and inks. However, aluminum powder is highly reactive and easily oxidized. It also poses explosion risks during production. The auto-ignition temperature is around 590°C, and the dust explosion limit is about 40 mg/m³.

Traditional wet ball milling can produce high aspect ratio flakes. However, it has drawbacks like solvent residues and high drying energy.

It also creates environmental problems. Dry ultrafine grinding is more efficient but faces new challenges. It must avoid over-grinding and control oxidation. It must also maintain uniform particle size distribution.

In advanced fields like automotive coatings and electronic encapsulation, requirements are strict. Aluminum powder must have D50 < 5 μm and SPAN < 1.5. The ACM meets these strict conditions. It allows continuous, contamination-free production under nitrogen protection. This promotes the upgrade of aluminum powder from filler to functional material.

Working Principle of Air Classifier Mill for Aluminum Powder

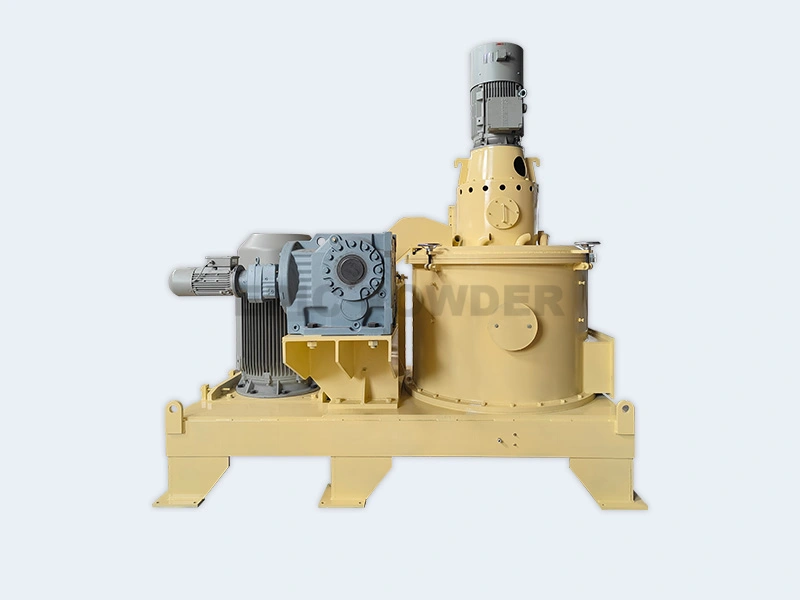

The air classifier mill is a high-speed impact pulverizer. It integrates a turbine classifier for “pulverization + classification.”

Core structure:

- Pulverizing Chamber: High-speed rotor (>6000 rpm). Material enters via airflow. It generates shear, impact, and friction. This breaks flaky aluminum uniformly.

- Classifier Wheel: Above the chamber. Uses centrifugal force and airflow difference. Separates particles dynamically. Fine powder exits with airflow. Coarse powder recirculates. Prevents over-grinding.

- Auxiliary Systems: High-pressure blower supplies airflow. Nitrogen seal controls oxygen <1%. Cyclone and bag filter collect product.

Workflow: Pre-crushed aluminum enters the mill. Nitrogen atmosphere protects it. Material accelerates to 80–150 m/s. Autogenous collisions pulverize it. Classifier wheel (2000–5000 rpm) cuts particle size. Laser analyzer monitors D97 (5–20 μm).

Advantages:

- vs. jet mills: mechanical impact suits ductile aluminum; 30% higher efficiency.

- vs. ball mills: dry process; no liquid media; higher purity.

Process Optimization for Ultrafine Aluminum Powder Pulverization

In production, broyeur classificateur à air requires key parameter optimization for aluminum powder:

- Feed Size: 50–200 μm. Prevents clogging.

- Airflow & Speed: 150–300 m³/h; rotor 8000 rpm. Achieves D50 3–8 μm flaky powder.

- Additifs: 0.5%–2% stearic acid or silane. Reduces surface energy. Prevents agglomeration and oxidation.

- Cooling: Nitrogen circulation. Temperature <60°C. Suppresses oxidation.

Typical Process: Coarse powder (D50=50 μm) processed. Yield 1–5 t/h. Energy <100 kWh/t. High classification precision. Aspect ratio 80–120. Outperforms conventional dry mills.

Safety: Fully enclosed explosion-proof design. Static grounding. Dust monitoring. Meets ATEX standards.

| Application Field | Particle Size (μm) | Functional Advantage |

|---|---|---|

| Automotive/Architectural Coatings | D97 < 10 | Metallic luster, strong weather resistance |

| Printing Inks | D50 2–5 | High coverage, parallel orientation |

| Plastic Composites | D50 < 8 | Conductive shielding, enhanced strength |

| Cosmetics/Fireworks | D50 5–15 | Pearlescent effect, safe dispersion |

| Aerospace Materials | D97 < 5 | Lightweight filler, thermal shielding |

Poudre épique

Epic Powder leads in ultrafine pulverization. Offers complete Air Classifier Mill systems with smart control and online monitoring. Ideal for flammable materials like aluminum. Capacity 0.5–10 t/h. SPAN<1.2. Enables green, efficient production.

Choose Epic Powder Air Classifier Mill — precise, safe aluminum pulverization. Contact us for custom solutions. Co-create value in metallic pigments!