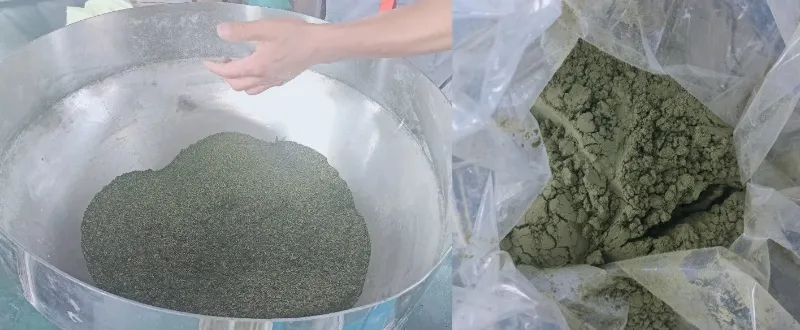

Matcha, a unique form of green tea powder, is celebrated worldwide for its delicate texture, bright color, and rich nutritional value. Achieving high-quality matcha powder with a fine mouthfeel, vivid color, and excellent solubility relies fundamentally on precise grinding and classification processes. The application of 공기 분류 밀 for matcha grinding technology provides an exceptionally efficient and stable solution for this fine processing, as it enables the simultaneous ultra-fine grinding and precise classification of the tea leaves under controlled, low-heat conditions, which is crucial for preserving the volatile flavors and vibrant chlorophyll.

Special Requirements for Matcha Grinding

Traditional green tea grinding methods struggle to achieve the ultrafine fineness required for matcha (typically within the range of 3–20 µm). More importantly, manufacturers must strictly control several critical aspects during the grinding process:

- Low-temperature grinding: Matcha is extremely sensitive to heat. High temperatures destroy valuable chlorophyll (causing color darkening) and polyphenols, and may produce burnt flavors.

- Oxidation prevention: During grinding, aromatic compounds and lipids in the tea leaves are easily oxidized, affecting the flavor.

- Uniform and ultrafine particle size: Only when the powder reaches micro- or nano-scale fineness can matcha truly “suspend” in water or liquid rather than settle, creating a smooth and full-bodied taste.

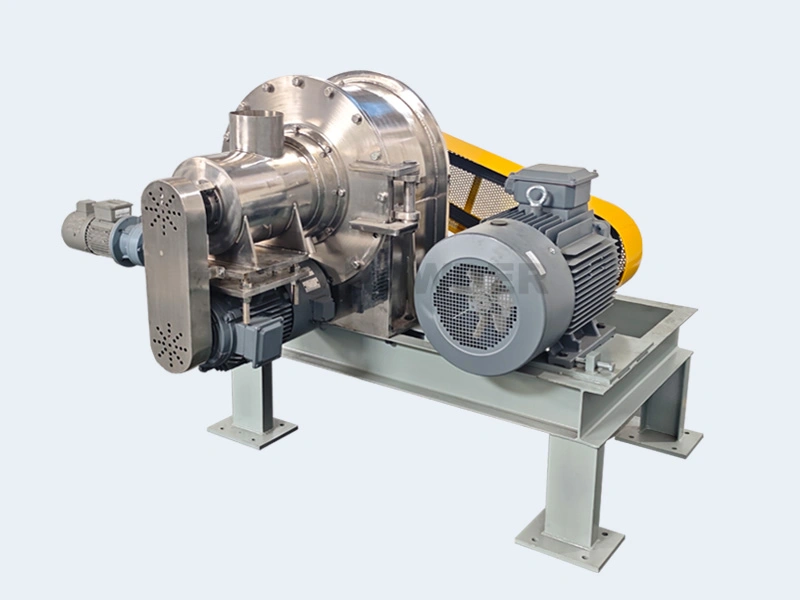

Application of Air Classifier Mill for Matcha

그만큼 classifying mill grinding system integrates fine grinding and precise classification within one piece of equipment. Using a high-speed rotating classifier wheel under strong airflow, it enables accurate control of particle size. Its key advantages include:

- Low-temperature grinding: High-speed airflow dissipates grinding heat, preventing matcha discoloration.

- Precision classification: The classifier wheel speed is adjustable, keeping matcha particle size consistently within 5–15 µm.

- Uniform particle size distribution: Concentrated fine powder distribution enhances smoothness and solubility.

- Closed system design: Prevents external contamination and ensures hygienic purity of the tea powder.

Applications and Advantages

Matcha powder processed by air classify mill grinding features uniform particle size, preserved aroma, and a bright green color. It is widely used in:

- Premium beverages (matcha lattes, smoothies)

- Baked goods (matcha cakes, cookies)

- Functional health products and cosmetics

Compared with traditional stone mills or mechanical grinders, classifying mills offer significant advantages in energy efficiency, hygiene control, and production consistency, making large-scale, standardized manufacturing possible.

결론

The quality of matcha depends on the precision and stability of its grinding and classification technology. By using the classifying mill grinding system, manufacturers can achieve finer and more uniform powder. This process also minimizes heat buildup and preserves the natural color, aroma, and nutrients of matcha.

EPIC Powder has over 20 years of expertise in ultrafine grinding and precision classification. The company provides matcha producers with efficient, low-temperature, and hygienic classifying mill solutions. The system combines grinding and classification in one step. It ensures stable and controllable fineness with contamination-free operation. It is especially suitable for high-end matcha production with strict quality standards.

With this advanced technology, EPIC Powder helps customers improve matcha powder fineness, color brightness, and aroma retention. The company sets a new benchmark for the high-end processing of natural plant powders.