Invoering

Harde koolstofprecursor uit biomassa is een primair koolstofmateriaal. Het wordt verkregen uit natuurlijke biomassa (bijv. rijstkaf, hout, kokosnoot shell). Het proces gebruikt pyrolyse en carbonisatie onder een inerte atmosfeer. Het temperatuurbereik is gemiddeld (500–1200 °C). Het heeft aanvankelijk de ongeordende koolstoflagen en nanoporeuze structuur van harde koolstof. Maar het bevat meestal onzuiverheden. De chemische oppervlakte-eigenschappen zijn instabiel. De deeltjesgrootteverdeling is ongelijkmatig. Het kan daarom niet direct worden gebruikt voor anodes van lithium-/natriumbatterijen. Het vereist een fijne nabewerking.

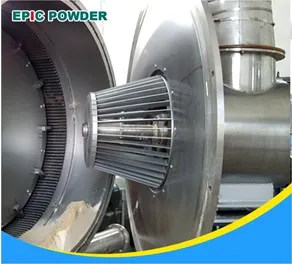

Bij de industrialisatie van harde koolstofanodematerialen is de verwerking van bulk- of grofkorrelige precursors tot micron-formaat poeders cruciaal. Deze poeders vereisen een uniforme deeltjesgrootte, extreem hoge zuiverheid en regelmatige morfologie. Qingdao Epic Powder Machinery Co, Ltd. is een professionele fabrikant van apparatuur voor poederverwerking. Het bedrijf heeft een grondige kennis van de prestaties van diverse apparatuur voor poederverwerking. De luchtclassificatiemolen die het produceert, is zeer geschikt voor de verwerking van harde koolstofprecursoren uit biomassa.

Waarom zou u een luchtclassificatiemolen kiezen voor uw verwerking?

De luchtclassificatiemolen integreert mechanisch slagslijpen en luchtclassificatie. Het werkingsprincipe sluit perfect aan bij de strenge verwerkingsvereisten van harde koolstofmaterialen. De molen heeft vier belangrijke voordelen:

1. Extreme zuiverheid: effectieve preventie van metaalverontreiniging

Batterijmaterialen hebben strikte beperkingen op metaalverontreinigingen (bijv. ijzer, nikkel, chroom). Deze verontreinigingen kunnen de levensduur en veiligheid van de batterij ernstig aantasten.

Voordeel: De ACM maalt op basis van botsing tussen deeltjes of tussen deeltjes en liner. Er zijn geen metalen maalmedia nodig (bijv. stalen kogels in een kogelmolen). Dit voorkomt fundamenteel metaalverontreiniging door slijtage van de media.

2. Nauwkeurige classificatie: het bereiken van een smalle deeltjesgrootteverdeling

Harde koolstofanodes vereisen een zeer uniforme en controleerbare deeltjesgrootteverdeling (PSD). Overmatige fijne deeltjes verminderen de efficiëntie van de eerste cyclus en verhogen de nevenreacties. Te veel grove deeltjes beïnvloeden de uniformiteit van de elektrodecoating en ion vervoer.

Voordeel: Het apparaat beschikt over een ingebouwd dynamisch classificatiewiel. Door de snelheid aan te passen, kan de fijnheid van het product (D50, D97) in realtime en nauwkeurig worden geregeld. Overmaatse deeltjes worden gescheiden en teruggevoerd naar de maalzone. Dit zorgt ervoor dat alleen gekwalificeerde deeltjes worden afgevoerd. Het garandeert een uitzonderlijke consistentie van batch tot batch.

3. Lagetemperatuurverwerking: behoud van de delicate microstructuur

De elektrochemische eigenschappen van harde koolstof hangen nauw samen met de unieke, ongeordende nanoporeuze structuur. Overmatige hitte tijdens de verwerking kan deze kritische structuur aantasten of beschadigen.

Voordeel: De luchtclassificatiemolen genereert tijdens bedrijf een grote hoeveelheid lucht. Deze lucht voert de warmte van het malen snel af. Het systeem blijft op een relatief lage temperatuur. Zo blijft de inherente poreuze structuur van de harde koolstofprecursor effectief behouden.

4. Morfologische modificatie: toenemende tapdichtheid

De impact en wrijving van snelle luchtstromen kunnen de scherpe randen van harde koolstofdeeltjes "afsnijden". Dit maakt hun morfologie regelmatiger.

Voordeel: Deze morfologie-optimalisatie helpt de tapdichtheid van het materiaal te verhogen. Tijdens de elektrodefabricage kan er meer actief materiaal per volume-eenheid worden gevuld. Dit verbetert uiteindelijk de energiedichtheid van de batterij.

Praktische toepassingsrichtlijnen van ACM

Om het potentieel van de apparatuur optimaal te benutten, dient u bij de verwerking van harde koolstofprecursoren uit biomassa rekening te houden met de volgende punten:

Controleer het vochtgehalte van het voer: Droog de precursor tot een vochtpercentage van ≤5-8%. Dit voorkomt materiaalaanhechting en verstopping van de apparatuur. Het garandeert een continue werking.

Optimaliseer de classificatie van de wielsnelheid: Bepaal de optimale snelheid op basis van de doeldeeltjesgrootte (bijv. D97 = 15 μm, 20 μm, 30 μm). Tests kunnen helpen deze snelheid te bepalen. Hogere snelheden leveren over het algemeen fijnere producten op.

Kies slijtvaste oplossingen: Gebruik slijtvaste materialen voor zeer schurende grondstoffen met een hoog asgehalte (bijvoorbeeld voorlopers op basis van rijstkaf). Wolfraamcarbide of keramiek zijn goede keuzes. Ze kunnen worden gebruikt voor het maken van voeringen en slijpcomponenten. Dit minimaliseert het risico op contaminatie door slijtage van de apparatuur.

Conclusie

De marktvraag naar batterijen neemt toe. Ze vereisen een hogere energiedichtheid, een langere levensduur en betere veiligheid. Dit vergroot de vraag naar hoogwaardige, goedkope anodes van hard koolstof. Het stelt ook hogere eisen aan de consistentie, zuiverheid en verwerkingsefficiëntie van het anodemateriaal.

De luchtclassificatiemolen heeft vele kernfuncties, waaronder contaminatiepreventie, nauwkeurige classificatie, verwerking bij lage temperaturen en morfologische modificatie. Dit maakt het een onmisbare sleutelmachine in de biomassa-hardkoolstofindustrie. Het biedt betrouwbare technische ondersteuning voor het verbeteren van de algehele prestaties van het eindproduct.

Qingdao Epic Powder Machinery Co., Ltd. beschikt over diepgaande technische expertise. Het bedrijf streeft ernaar om klanten wereldwijd uitgebreide ondersteuning te bieden. De diensten omvatten apparatuurselectie, ontwerp van procesoplossingen, installatie, inbedrijfstelling en aftersalesservice. Het helpt klanten de waarde van hun hardkoolstofprojecten te maximaliseren. Voor meer informatie over onze Air Classifier Mills (modellen: MJW-A, MJW-W, MJW-L, MJL-W, En ACM-lab), Alsjeblieft Neem contact op met het Epic Powder-team.