Jet mill and air classifier mill are two important powder grinding equipment. The two share some commonalities, e.g: both use air as the main working medium, both utilize the effect of air flow to classify the ground materials, and both are dry powder grinding equipment. However, there are more differences between them, including aspects such as the grinding principle, classification method, and grinding fineness, etc.

In this article, we will mainly summarize and analyze the differences between the two, providing a reference for your engineering selection:

The differences between the two

1.Working principle

| Equipment | Jet Mill | Air classifier mill |

| Grinding principle | Pure jet milling with no mechanical moving parts | Mechanical + airflow grinding: A high-speed rotor generates impact force to grind materials, while airflow assists in conveying and classification |

| Grading method | Built-in and external classification options, with particle size controlled by adjusting airflow velocity. | Built-in dynamic classifying wheel with adjustable rotor speed for control of particle size. |

| Energy source | Purely airflow-dependent operation,with higher energy consumption | Mainly mechanical impact, assisted by airflow, with relatively low energy consumption |

2. Structure and design

| Equipment | Jet mill | Air classifier mill |

| Core parts | Nozzle, grinding chamber, classifying wheel (optional), cyclone separator. | High-speed rotor, classifying wheel, lining plate, screen (optional) |

| Moving parts | No rotating grinding components (only the classifying wheel rotates) | The rotor rotates at a high speed (usually between 3,000 and 10,000 revolutions per minute). |

| Wear risk | Very low (no medium contact, suitable for high hardness materials) | Medium to high (rotor and liner plate may wear and require wear-resistant design) |

3. Performance parameters

| Equipment | Jet mill | Air classifier mill |

| Particle size distribution | Ultra-fine powder, narrow distribution | Medium fine powder, wide distribution |

| Capacity | Lower (small batch high precision production) | High mechanical impact efficiency, suitable for continuous mass production |

| Energy consumption | High | Relatively low |

| Purity control | Excellent (no pollution, suitable for medical and electronic grade materials). | General (metal wear may introduce impurities and require ceramic lining for protection). |

4. Applicable scenarios

| Equipment | Applicable scenarios |

| Jet mill | – High purity, ultra-fine powders (such as silicon carbide semiconductor powders, pharmaceutical raw materials). – Heat sensitive materials (cryogenic grinding). |

| Air classifier mill | – Large-scale production of medium-fine powders (such as coatings, fillers, pesticides). – Industrial grade products with less stringent purity requirements. – Where both grinding and classification are required. |

Summary

The above points are the differences between jet mill and air classifier mill. When selecting equipment, we need to comprehensively consider various factors, such as material characteristics, particle size requirements, purity requirements and cost, and choose the most suitable equipment with the highest cost performance.

For jet mill and air classifier mill: If high purity and fineness are strictly required, jet mill is the only option. If cost – effectiveness and production capacity are the priorities, the ACM (Air Classifier Mill) is a better choice.

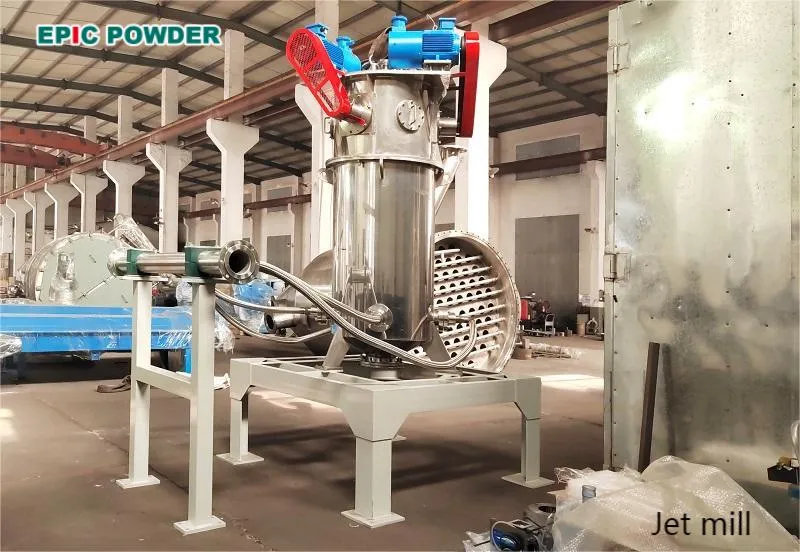

Qingdao Epic Powder Machinery Co., Ltd. is a professional manufacturer of powder processing equipment. Our products mainly include powder grinding equipment, classification equipment, modification equipment and related auxiliary equipment. Among them, jet mill and air classifier mill are two of our grinding equipment. (Our ACM mill includes 4 types: MJW-L, MJW-W, MJW-A, and MJL-W). After years of research and market testing, both of them feature stable quality and are well – received by consumers.

If you have relevant needs, please contact us. We have a professional team to provide full – process support, including pre – project technical consultation and solution design, equipment installation and commissioning, operator training, as well as after – sales equipment maintenance and technical upgrades.

Contact Epic Powder, and Let our specialized equipment empower your powder processing – for higher efficiency and more energy-saving.