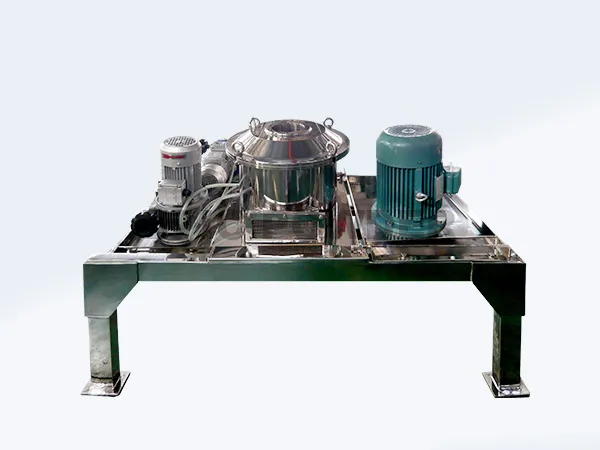

- Double-shaft structure, derived from the classic air classifier mill design.

- Built-in guide ring, stable flow field, suitable for high-efficiency grinding of medium-fine products.

- Different designs of crushing blades/hammers/rods and ring gears meet the crushing needs of materials with different characteristics.

- It can meet the pure production of all ceramics, and there is no increase of magnetic substances in the production process.

- Special design, easy to disassemble and assemble, can clean without dead ends, saving maintenance time.

- Airflow closed-loop design, no moisture increase, can be used as nitrogen circulation system, real-time monitoring and control of gas oxygen content.

Configuration

The Air Classifying Mill is designed to produce finer materials with sharper particle size distributions than most other impact milling technologies. In certain applications, a median particle size as low as 5 microns can be achieved.

The Air Classifying Mill is the main component of the size reduction system however, additional ancillary components are required for a fully functional system.

- A feeder is required to accurately dispense product into the milling system.

- A product collector is required to separate the product from the gas stream and collect the material.

- Airlocks are used for feeding the system, containing system pressure and product discharging.

- A fan is required to generate the airflow to convey, mill and classify the product.

- Adequately sized ducting is required to connect the system components and contain and convey the product.

- Instrumentation and valves are required to sense and regulate the various operating parameters of the system.

- A control system is required to operate, monitor and control the output of the system.

Parameter

| Model | 300 | 400 | 500 | 700 | 900 | 1100 |

|---|---|---|---|---|---|---|

| Motor Power(kw) | 30 | 22 | 30 | 45 | 75-90 | 110-132 |

| Rotating speed(rpm) | 7000 | 4350 | 3850 | 2760 | 2350 | 1920 |

| Motor Power(kw) | 1.5 | 5.5 | 5.5 | 7.5 | 15 | 30 |

| Rotating speed(rpm max) | 4500 | 3200 | 3000 | 3000 | 2200 | 2000 |

| Fineness (μm) | 10-300 | 10-300 | 10-300 | 10-300 | 10-300 | 10-300 |

| Capacity (kg/h) | 5-100 | 20-1000 | 30-1500 | 40-2000 | 80-4000 | 120-6000 |

Send Us A Message

Sed ut perspiciatis, unde omnis iste natus error sit voluptatem accusantium doloremque.

Related Caes

A well-known pigment factory in Jiangsu Province ordered EPIC pigment Air Classifier Mill

6 月 8, 2023

The pigment manufacturer is a ...

Read More →

Production line of pea protein isolate mechanical Air Classifier Mill of a company in Beijing

6 月 8, 2023

The client company is a ...

Read More →

Lithium cobalt oxide production line of a new material technology company in Tianjin City

6 月 8, 2023

This customer is a well-known ...

Read More →

Ternary material grinding production line of a recycling technology company in Guangdong

6 月 8, 2023

The client is a listed ...

Read More →